Provide you with the latest enterprise and industry news.

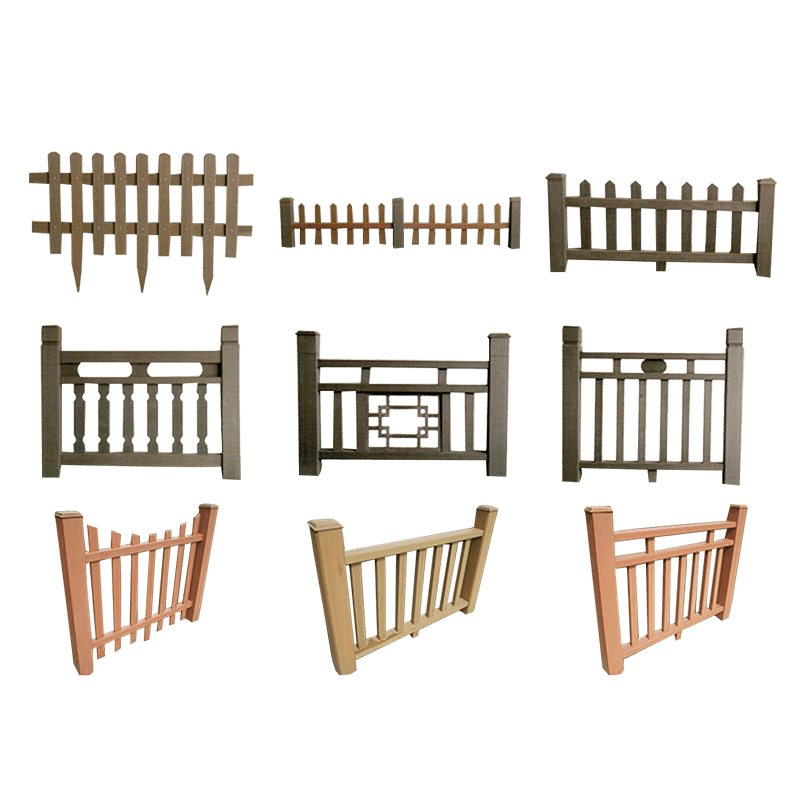

WPC (Wood-Plastic Composite) guardrails often contain additives and coatings to enhance their durability, appearance, and performance. Here are some common additives and coatings used:

Additives:

UV Stabilizers:

Protect the WPC material from the harmful effects of ultraviolet (UV) radiation.

Prevents fading, discoloration, and degradation due to sun exposure.

Antioxidants:

Prevent the oxidation of plastic components within the WPC, extending the material’s lifespan.

Protect against thermal degradation during manufacturing and usage.

Coupling Agents:

Improve the bonding between wood fibers and plastic polymers.

Enhance the mechanical properties and stability of the composite material.

Colorants and Pigments:

Provide consistent color throughout the material.

Offer various aesthetic options to match design preferences.

Lubricants:

Facilitate the manufacturing process by reducing friction.

Improve the surface finish and processing efficiency.

Antimicrobial Agents:

Inhibit the growth of mold, mildew, and bacteria on the surface.

Enhance hygiene and longevity, especially in outdoor environments.

Coatings:

Protective Coatings:

Applied to the surface of WPC guardrails to provide additional protection against weathering and environmental factors.

Enhance resistance to moisture, stains, and abrasion.

Waterproof Coatings:

Provide an extra layer of protection against water infiltration.

Essential for applications in humid or wet environments.

Anti-Graffiti Coatings:

Allow for easy removal of graffiti and stains.

Maintain the aesthetic appearance of the guardrails in public areas.

UV-Resistant Coatings:

Enhance the UV stability provided by internal UV stabilizers.

Prolong the appearance and structural integrity of the guardrails when exposed to direct sunlight.

Benefits of Additives and Coatings:

Enhanced Durability: Additives and coatings significantly improve the lifespan and performance of WPC guardrails.

Reduced Maintenance: Protective coatings and internal stabilizers reduce the need for frequent maintenance and repairs.

Improved Aesthetics: Colorants and UV-resistant coatings maintain the appearance of the guardrails over time.

Environmental Resistance: Additives like antimicrobial agents and waterproof coatings enhance resistance to various environmental factors, including moisture and microbial growth.

Implementation:

Manufacturing Process: Additives are typically mixed with wood fibers and plastic during the manufacturing process to ensure even distribution.

Surface Application: Coatings are applied to the finished product, either through spraying, brushing, or dipping, depending on the type of coating and desired finish.

By incorporating these additives and coatings, WPC guardrails become more robust, visually appealing, and better suited for various applications, from residential settings to commercial and public infrastructures.

English

English Español

Español