Provide you with the latest enterprise and industry news.

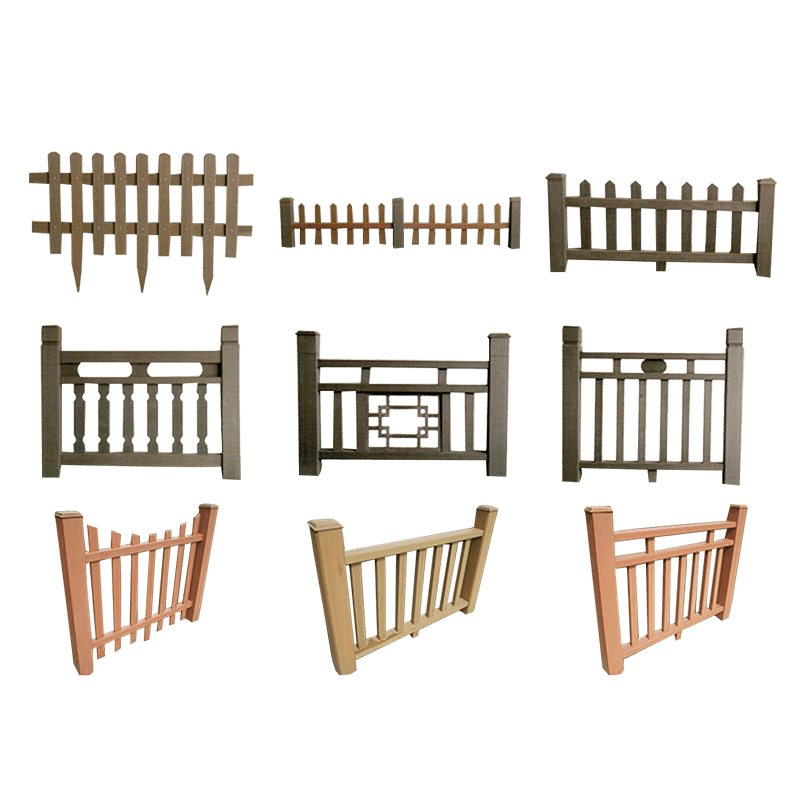

Comparing WPC (Wood-Plastic Composite) guardrails to traditional wood and metal guardrails involves evaluating various factors, including durability, maintenance, aesthetics, cost, and environmental impact. Here’s a detailed comparison:

Durability

WPC Guardrails:

Highly resistant to rot, mold, and insect damage due to the plastic component.

Durable and able to withstand harsh weather conditions without warping or splintering.

Generally UV-resistant, reducing the risk of fading and degradation from sun exposure.

Wood Guardrails:

Prone to rot, mold, and insect damage, especially if not properly treated and maintained.

Can warp, crack, or splinter over time, particularly in harsh weather conditions.

Requires regular sealing, staining, or painting to protect against UV damage and moisture.

Metal Guardrails:

Extremely durable and resistant to impact damage.

Can rust and corrode if not properly treated or coated, especially in moist or salty environments.

Typically requires periodic maintenance to prevent rust and maintain appearance.

Maintenance

WPC Guardrails:

Low maintenance compared to wood and metal.

Requires occasional cleaning with soap and water.

Does not need sealing, staining, or painting.

Wood Guardrails:

High maintenance; requires regular sealing, staining, or painting to maintain appearance and durability.

Needs frequent inspections for rot, mold, and insect damage.

Repairs and replacements are more common due to wear and tear.

Metal Guardrails:

Moderate maintenance; requires periodic inspections for rust and corrosion.

May need repainting or recoating to prevent rust and maintain aesthetics.

Can be more challenging to repair if damaged.

Aesthetics

WPC Guardrails:

Offers a variety of colors, textures, and finishes that mimic the appearance of natural wood.

Consistent appearance over time with less risk of fading or discoloration.

Customizable to match specific design preferences.

Wood Guardrails:

Natural, traditional look that is often preferred for its aesthetic appeal.

Can be painted or stained in various colors to match design schemes.

May develop a weathered look over time, which some people find appealing.

Metal Guardrails:

Modern, sleek appearance; available in various finishes and styles.

Can be painted or powder-coated in different colors.

May look more industrial or institutional, depending on the design.

Cost

WPC Guardrails:

Initial cost is generally higher than wood but lower than high-quality metal guardrails.

Long-term cost is lower due to reduced maintenance and longer lifespan.

Wood Guardrails:

Initial cost is lower than WPC and metal guardrails.

Long-term cost can be high due to frequent maintenance, repairs, and replacements.

Metal Guardrails:

Initial cost is the highest among the three materials.

Long-term cost is moderate; requires less frequent maintenance than wood but more than WPC.

Environmental Impact

WPC Guardrails:

Often made from recycled materials, reducing environmental impact.

Long lifespan reduces the need for frequent replacements, lowering overall environmental footprint.

Wood Guardrails:

Can be sourced from sustainable forestry, but this depends on the supplier.

Requires chemical treatments for durability, which can have environmental impacts.

Shorter lifespan means more frequent replacements and higher resource use.

Metal Guardrails:

High energy consumption during production, especially for steel and aluminum.

Can be recycled, but the process can be resource-intensive.

Long lifespan reduces the frequency of replacements.

Installation

WPC Guardrails:

Moderate installation process; similar to wood guardrails.

Requires proper support and spacing for stability.

Wood Guardrails:

Generally straightforward installation, but requires more frequent checks and adjustments over time.

Needs proper treatment to avoid early degradation.

Metal Guardrails:

More complex installation process, often requiring specialized tools and skills.

Requires secure anchoring to prevent movement and ensure safety.

WPC Guardrails: Offer a good balance of durability, low maintenance, and aesthetic flexibility, making them a cost-effective and environmentally friendly choice for many applications.

Wood Guardrails: Preferred for their natural appearance and traditional look but require high maintenance and have a shorter lifespan.

Metal Guardrails: Provide excellent durability and a modern appearance but come with higher initial costs and moderate maintenance requirements.

English

English Español

Español