Provide you with the latest enterprise and industry news.

With the acceleration of urbanization and the continuous improvement of people's requirements for safety and environmental protection, WPC (wood plastic composite) guardrails, as a new type of safety facility, have gradually come into people's view. With its superior weather resistance, environmental protection and aesthetics, WPC guardrails have become an ideal choice for public places such as roads, scenic spots, and parks. It not only solves many defects of traditional wood guardrails, but also promotes the sustainable development of architecture and landscape design through innovative material design.

WPC guardrails are mainly made of wood fiber and plastic (such as polyethylene, polypropylene, etc.) through high-temperature pressing, combining the natural texture of wood with the durability of plastic. This composite material not only retains the appearance and touch of wood, but also overcomes the problems of easy corrosion and cracking of natural wood during use. The emergence of WPC guardrails marks the perfect combination of wood and plastic, and has become a highlight that cannot be ignored in modern architecture and landscape design.

Compared with traditional wood, WPC materials have significantly improved their service life. It not only has good water resistance and UV resistance, but also is not affected by climate change and can maintain stable physical properties for a long time. This makes WPC guardrails an ideal choice for a variety of outdoor environments, whether it is exposed to sunlight or rainy and snowy weather, they can maintain their original appearance and function.

One of the most significant advantages of WPC guardrails is their extremely high durability. Compared with traditional wood, WPC materials are not easily attacked by humid environments and insects, and are not easy to rot, deform, or crack. Whether it is a wet rainy season or a dry summer, WPC guardrails can maintain long-term stability, greatly reducing the frequency of maintenance and replacement. This high durability allows WPC guardrails to maintain efficient functionality and beauty during long-term use.

The maintenance cost of WPC guardrails is very low. Unlike traditional wooden guardrails that require regular painting and anti-corrosion treatment, WPC guardrails do not require too much manual maintenance, only regular cleaning of surface dust. This not only reduces long-term maintenance costs, but also makes WPC guardrails an economical and environmentally friendly choice.

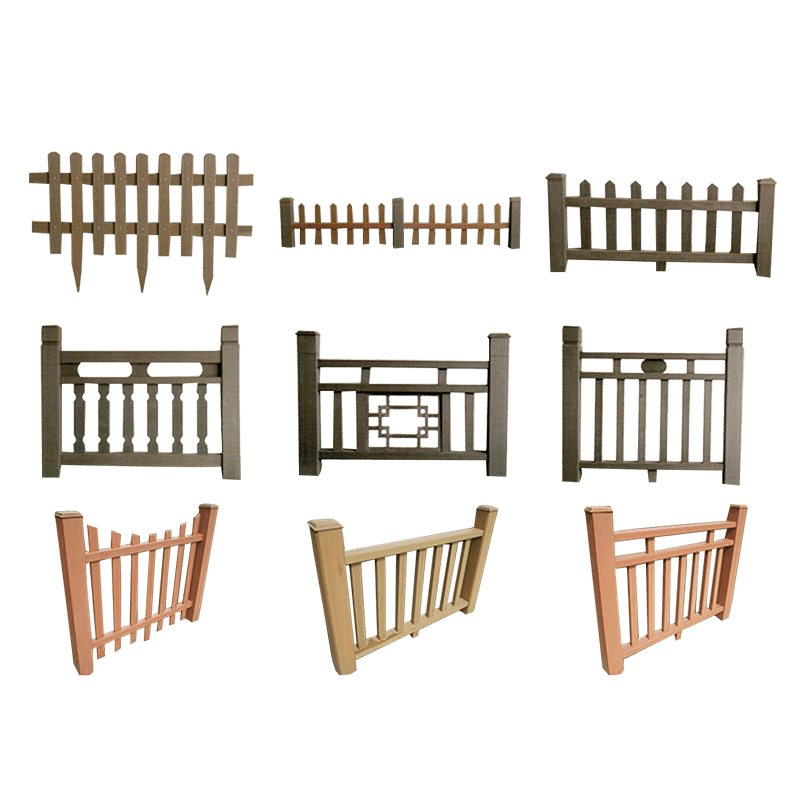

WPC guardrails are highly flexible in design and can be created in a variety of shapes and colors according to different application requirements and design styles. Its surface can be processed into a variety of textures such as wood grain and stone grain, which fully retains the natural beauty of wood while avoiding problems such as wood perishability and color change.

Due to the diversity of its materials, WPC guardrails can be used in various scenarios, including urban streets, park scenic spots, residential areas, commercial areas, etc. Whether in natural landscapes or in artificial environments, WPC guardrails can perfectly blend with the surrounding environment and enhance the overall landscape effect. At the same time, WPC materials have strong stain resistance and weather resistance. Even in harsh environments, the surface of the guardrail is not easy to leave stains or fade, and it always remains beautiful.

As an environmentally friendly material, WPC guardrails not only avoid a large amount of natural wood resource consumption, but also have low carbon emissions in its production process, which meets the requirements of sustainable development. WPC materials are mainly made of wood fiber and plastic, and the wood fiber part can come from recycled wood and agricultural waste, which greatly reduces dependence on natural forest resources. In addition, WPC materials themselves can also be recycled and reused, further reducing the burden on the environment.

With the global emphasis on environmental protection and resource conservation, WPC guardrails have been widely used and promoted as a sustainable development product. It not only meets the high requirements for environmental protection, but also provides consumers with a cost-effective choice.

With the continuous improvement of people's requirements for environmental protection, durability and beauty, the market demand for WPC guardrails has shown a rapid growth trend. Especially in urban construction and garden landscape, the application of WPC guardrails has gradually replaced traditional wood guardrails and become the mainstream choice. In addition, with the advancement of technology, the performance and manufacturing process of WPC materials are also constantly improving, which has gradually reduced the cost of this material and further increased the market penetration rate.

Whether it is fences in public places, garden guardrails in residential areas, or sightseeing facilities in scenic spots, WPC guardrails have shown great application potential. It is expected that in the next few years, WPC guardrails will be more widely used worldwide and become an indispensable part of architectural and landscape design.

With its superior durability, low maintenance cost, environmental protection and beauty, WPC guardrails are becoming an ideal safety facility in modern urban construction. As people's demand for sustainable development continues to increase, WPC guardrails will continue to be widely used in various public places and private residences, becoming an environmental protection trend leading future urban construction. Whether from the perspective of energy conservation and emission reduction or from the perspective of aesthetics and safety, WPC guardrails are undoubtedly the ideal choice for modern society.

English

English Español

Español