Provide you with the latest enterprise and industry news.

In today’s rapidly evolving world, where sustainability and durability are at the forefront of construction and infrastructure design, WPC (Wood Plastic Composite) guardrails have emerged as a popular choice for enhancing safety, aesthetics, and environmental responsibility. Combining the best qualities of both wood and plastic, WPC guardrails offer a unique set of benefits that traditional materials like wood, metal, or concrete simply cannot match.

The manufacturing process of WPC guardrails involves heating the wood fibers and plastic to create a homogeneous mixture that can be shaped into the desired form. The final product is a sturdy, low-maintenance material that is resistant to the environmental challenges that often affect traditional wood or metal guardrails, such as weathering, rotting, rusting, and UV degradation.

One of the key benefits of WPC guardrails is their exceptional durability. Traditional wood guardrails can be susceptible to rotting, cracking, or splintering when exposed to moisture, while metal guardrails can rust over time. WPC guardrails, on the other hand, are highly resistant to these common issues. The plastic component of the composite material provides protection from moisture, preventing the guardrails from warping or decaying, while the wood fibers lend the material a natural appearance without sacrificing strength. As a result, WPC guardrails have a much longer lifespan, requiring less frequent maintenance and replacement.

WPC guardrails are engineered to withstand a wide range of environmental conditions, making them an excellent choice for both urban and rural infrastructure. Whether exposed to rain, snow, intense heat, or freezing temperatures, WPC guardrails retain their integrity and functionality. The material’s resistance to moisture makes it ideal for regions with high humidity or rainfall, where traditional wood guardrails might weaken and degrade. Additionally, the UV-stabilized surface ensures that the color and texture of the guardrails remain intact, even after prolonged exposure to sunlight.

As sustainability becomes an increasingly important consideration in construction, WPC materials offer a more environmentally friendly alternative to traditional guardrail materials. Since WPC guardrails are made from recycled plastic and wood fibers, they help reduce the need for virgin resources. Moreover, the production process for WPC guardrails is typically less energy-intensive than that of metal or concrete alternatives. The ability to reuse plastic waste in manufacturing also helps to address the growing concern over plastic pollution, making WPC guardrails an eco-conscious choice for infrastructure projects.

Unlike wood, which requires periodic treatment with stains, paints, or preservatives to protect it from the elements, WPC guardrails need minimal maintenance. The material does not require repainting, and it does not need to be sealed to prevent moisture penetration. Cleaning is also simple—WPC guardrails can be washed with soap and water, ensuring that they continue to look new and perform well with little effort. This reduced maintenance requirement translates to cost savings over time, as property managers and municipalities do not need to allocate resources for regular upkeep.

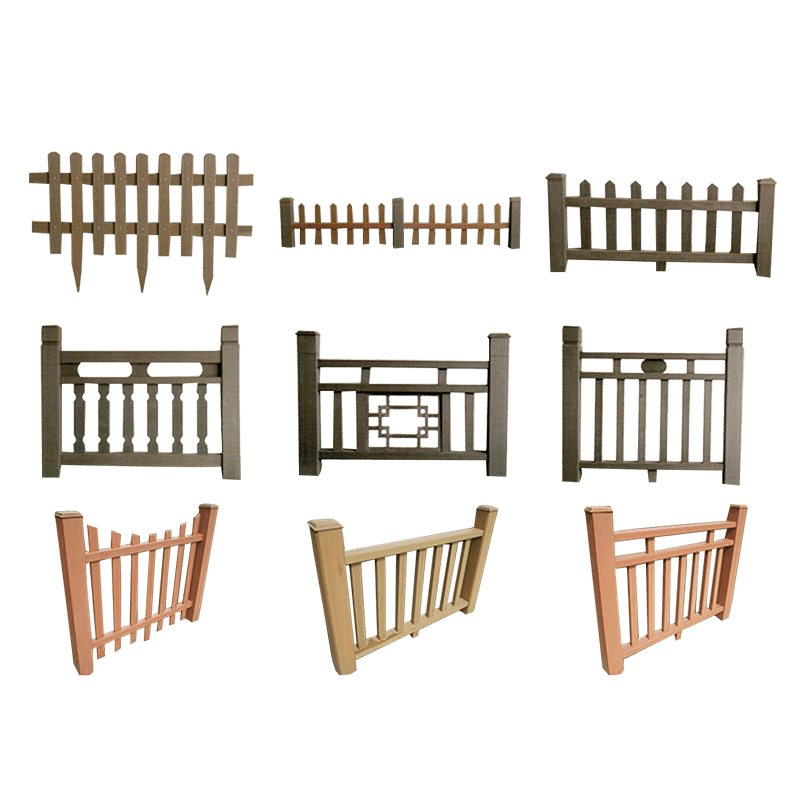

WPC guardrails provide a natural, wood-like appearance without the downsides of traditional wood materials. They can be molded into various shapes, sizes, and finishes to suit the specific aesthetic requirements of a project. Available in different colors and textures, WPC guardrails can complement a variety of design styles, from rustic to contemporary. Their versatile appearance makes them an ideal choice for urban developments, parks, and pedestrian walkways, where visual appeal is just as important as safety and durability.

Safety is always a top priority in the design of guardrails, and WPC guardrails are no exception. The materials used in the construction of these guardrails offer high-impact resistance, ensuring that they can withstand accidents and vehicle collisions without breaking or causing further damage. This makes WPC guardrails suitable for highways, roadsides, and areas with high traffic volumes. Additionally, the smooth surface of WPC guardrails reduces the risk of injury in the event of contact, making them safer for pedestrians and cyclists.

The versatility and performance of WPC guardrails make them suitable for a wide range of applications across various sectors. Some of the most common areas where WPC guardrails are used include:

Roads and Highways WPC guardrails are commonly used along roadways and highways to ensure the safety of drivers and passengers. Their durability and weather resistance make them an ideal choice for withstanding the harsh conditions typically found along busy roads. Additionally, WPC guardrails provide a modern, sleek appearance that can enhance the visual appeal of the infrastructure.

Pedestrian Walkways and Parks In urban areas, WPC guardrails are used along pedestrian walkways, bike lanes, and parks. These guardrails provide safety without compromising the natural aesthetic of the environment. Whether in a city park or along a scenic trail, WPC guardrails offer both functional and visual benefits, ensuring that pedestrians and cyclists are protected while preserving the beauty of the surroundings.

Bridges and Overpasses WPC guardrails are often utilized on bridges and overpasses, where they are exposed to both vehicle traffic and environmental elements. The materials' resistance to corrosion and wear makes them an excellent option for these types of infrastructure, where long-term performance and durability are crucial.

Public and Commercial Spaces In commercial and public spaces, such as malls, shopping centers, and recreational facilities, WPC guardrails are used for decorative as well as functional purposes. Their modern appearance and ease of maintenance make them a popular choice for areas that require both aesthetic appeal and durability.

Coastal and Marine Areas In coastal regions, where traditional materials can suffer from saltwater corrosion, WPC guardrails provide a corrosion-resistant alternative. Their ability to withstand extreme weather conditions, including high humidity and salt exposure, makes them a reliable choice for coastal infrastructure.

English

English Español

Español